When proceeding through the core phases of an epoxy project, you'll eventually get to a point where you need to pour your epoxy resin mixture onto your substrate or resin mold. It's at this point that a number of things can go wrong, if you're not fully aware of what they are.

Though epoxy resin is beautiful and strong, it doesn't default to that. Instead, it takes some care and deliberation during the epoxy process to achieve that iconic finish. This isn't to say that it's particularly complex or difficult, but that if you allow yourself to make a mistake, you probably will.

In this article, we'll be discussing 5 of the most common mistakes people tend to make during the pouring phase of an epoxy project. This phase is relatively short but still very important, so it's likewise important that you understand how to perform it.

The core phases of an epoxy project

The core epoxy project phases are as follows:

- Obtaining your epoxy.

- Measuring your epoxy.

- Mixing your epoxy.

- Pouring your epoxy.

- Curing your epoxy.

We've already written similar articles on shopping for epoxy, measuring epoxy batches, and mixing them afterward. So naturally, we'll be considering the next step: pouring your epoxy.

The 5 most common mistakes when pouring epoxy resin

Pouring your epoxy is easy once you know what not to do.Here's a list of the 5 mistakes we'll be addressing here:

- Pouring before the batch is fully mixed.

- Pouring out the resin batch too quickly.

- Pouring epoxy onto an unprepared substrate.

- Pouring from too high above the substrate.

- Pouring too much epoxy at once.

As with our other epoxy phase articles, we'll go through our list one by one, starting from the top.

Mistake #1: Pouring before the batch is fully mixed.

Prior to pouring, it's important to make sure you've fully mixed your resin batch. Blending the batch usually takes about 3 to 5 minutes total, though this can vary by batch size, resin type, and the tools you're using to mix it, such as stir sticks or a mixing drill bit.

Because the amount of time varies between resin brand and variant, you should also closely read the instructions included with your chosen resin brand.

For users of our UltraClear Epoxy Resins, you'll also find digital versions of our instructions on the following pages:

- Digital instructions for UltraClear Bar & Table Top Epoxy

- Digital instructions for UltraClear Deep Pour Epoxy

- Digital instructions for UltraClear Art & Craft Epoxy

How to avoid this problem:

As indicated above, you can avoid this issue entirely by fully blending your epoxy resin batches before you pour them. You can learn more about how to mix epoxy in our epoxy mixing guide.

Prevent mixing accidents! Click here and read about common slip-ups to avoid.

Mistake #2: Pouring out the resin batch too quickly.

Another issue that can occur is air bubble formation caused by pouring out your resin too quickly.

The most consistent concern throughout each phase of an epoxy project is the possibility of air bubbles forming in your resin and become difficult to remove. Though air bubble removal is a standard step, typically performed after pouring, the possibility of air bubbles manifesting exists in every phase.

The primary issue with air bubbles is that, while you can remove them after pouring, if there are too many it may be difficult or impossible to get them all, leaving behind blemishes in your epoxy resin finish.

How to avoid this problem:

To prevent this issue from occurring, simply pour the resin out of your mixing container smoothly and gradually. Avoid rushing the process, so that you can achieve optimal results.

Click here for our guide on how to pour epoxy properly

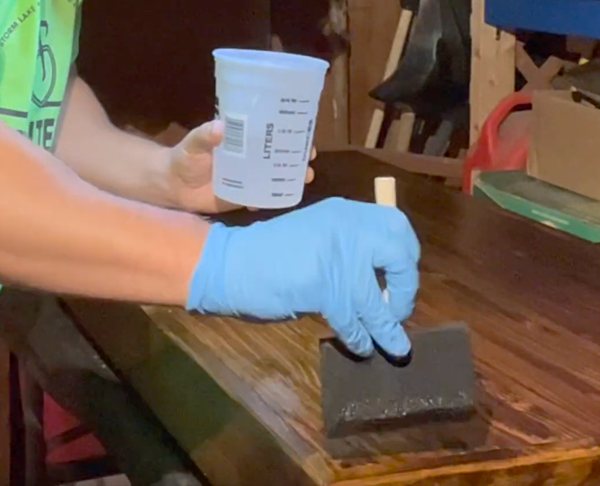

Mistake #3: Pouring epoxy onto an unprepared substrate.

Third in our list of mistakes is pouring epoxy onto an unprepared substrate.

An unprepared substrate can mean a dirty and/or wet surface, or it can mean a substrate that hasn't had a seal coat. Ensuring your substrate is ready for the epoxy is important to avoid a variety of issues, from air bubbles to curing issues to simple aesthetic blemishes and imperfections.

How to avoid this problem:

The issues caused by this can be easily avoided by first preparing your uncoated surfaces. This involves first making sure they're clean, then (in most cases) applying an epoxy seal coat to drive out air from any surface-level pores.

These two tasks are precursors to an eventual flood coating of epoxy.

Did you know: Cleaning epoxy surfaces is remarkably easy—learn more here!

Mistake #4: Pouring from too high above the substrate.

Fourth out of our list of five is the mistake of pouring from too high above your substrate (or resin mold) surface.

When epoxy is being poured out of a container, you want it to be relatively close to the surface you're pouring it onto. The further it travels, the more likely it is to pull air into its viscous mass. When this happens, you're likely to end up with excessive air bubbles, which can likely still be removed, but nonetheless increases the chance of some remaining as an undesirable imperfection in your final epoxy finish.

How to avoid this problem:

As with the other mistakes on our list, avoiding the problems caused by this one is simple once you're aware of the causes.

When pouring, try to keep the container no more than several inches above the surface to minimize the fall distance. It's also a good idea to move slowly and smoothly as you pour to spread the epoxy out evenly. Though epoxy is self-leveling, you can aid it in this process by deliberately coating any spaces that aren't already covered.

You can learn more about pouring epoxy in our guide to that phase of the process.

Mistake #5: Pouring too much epoxy at once.

Fifth and final from our list of mistakes is pouring too much epoxy at once.

What we mean by this is pouring enough epoxy that the resulting coat exceeds the recommended maximum for a single layer.

Most epoxy resins self-level, reaching a point of equilibrium. For many table top resins, the epoxy will self-level to 1/16 inch. For certain premium resins, however, such as our UltraClear Bar & Table Top Epoxy, the self-leveling thickness can be a thicker, more durable 1/8 inch layer. The issue with going beyond these natural depths is related to the viscosity of the epoxy.

Pouring an individual coating beyond an epoxy's self-leveling thickness can make it too thick for air to escape through, leading to air bubble formation within the epoxy finish.

When epoxy is applied to a substrate, any air that gets caught in it will attempt to escape by rising to the top and surfacing. Because epoxy is viscous, if a layer is too thick, the air may not manage to reach the surface, instead becoming suspended within the resin as it begins curing and hardening.

Naturally, this is a problem best avoided.

How to avoid this problem:

Once again, understanding the causes of a problem leads to easy prevention. To avoid this particular mistake, avoid pouring overly thick layers. Let the epoxy's self-leveling trait handle the thickness part, and just make sure the whole substrate is covered.

In most situations, epoxy will overflow if there's more than enough, but if you're using guards or have a raised trim, it likely won't be able to. This is the most likely time for this problem to occur.

Instead, try to pour a single layer that doesn't over extend, and allow the epoxy to partially cure before applying additional layers.

Additional Resources

Here are some additional resources you may find useful:

- How thick should bar top epoxy be? - Learn how thick your epoxy finish should be in this explainer.

- Epoxy resin FAQs: The curing phase - After pouring comes the curing phase. See answers to related questions here!

- How epoxy resin "budget brands" compromise your health and safety - Be wary of shady "budget brand" dealers, which offer cheap epoxy with hidden flaws.

Have questions? Want advice? Contact us!

If you have any questions about pouring epoxy resin, or if you'd like assistance in planning an epoxy project, please reach out to us at UltraClear Epoxy—our epoxy experts are ready to assist!

You can contact us via phone or email here. During business hours, you can also text chat online with one of our resin specialists by clicking the Help button at the bottom of your screen.

In our online store, you'll find a variety of useful tools and supplies, ideal for resin projects, plus our award-winning UltraClear Bar & Table Top Epoxy and our UltraClear Deep Pour Epoxy.