Measuring out your epoxy batch is the first step you'll take after you open the two component bottles. It's relatively simple step, really, but there are a few things that can go wrong if you're not aware of some of the details.

Because measuring properly is so important, we want to make sure that any of our readers fully understands how to do it properly, so that they can avoid a headache later.

In this article, we'll talk about 4 mistakes that inexperienced epoxy users often make when measuring out their epoxy batches.

The 4 biggest mistakes people make when measuring epoxy.

In our experience, there are 4 distinct mistakes that people make without realizing when measuring for a batch of epoxy resin. These are generally things that might not seem like they'd be a big problem.

Here's a list of the mistakes we'll be discussing in this article:

- Adding the epoxy components with the wrong ratio.

- Measuring by weight, rather than weight.

- Using components when they're too cold or too warm.

- Pouring your components into the wrong type of container.

Each of these mistakes can be easily avoided once you know why they're a problem. Let's take a look, starting from the top.

Mistake #1: Adding the epoxy components to the wrong ratio.

The most common mistake we've seen people make is to measure out their epoxy resin components to the wrong ratio. Because there are various types of epoxy resin, each with their own mixing ratio, it's essential to be sure what proportions your chosen epoxy requires to cure.

Let's use our epoxy resins as an example. Here's what they require:

- UltraClear Bar & Table Top Epoxy: 1:1 mixing ratio, resin to hardener.

- UltraClear Deep Pour Epoxy: 2:1 mixing ratio, resin to hardener.

As you can see, there's a slight different in the mixing ratio of these two resin products. Our Deep Pour Epoxy, which runs thinner and is less viscous than the others, requires less hardener than our Table Top Epoxy.

How to prevent this mistake:

Before you measure your epoxy batch, always make sure you know your resin's mixing ratio. This will ensure you measuring the correct amounts of each component.

Mistake #2: Measuring by weight, rather than volume.

Another mistake some resin users make is to measure their epoxy components by weight rather than volume.

Epoxy starts off as two different components: resin and hardener. Each of these components has a different density level. When measured out in equal volume, they weigh different amounts. For example, 16 fluid ounces of hardener will be lighter than 16 fluid ounces of resin. Because of this, attemping to use weight-based measurements ends up being imprecise and can often lead to problems during mixing and curing.

How to prevent this mistake:

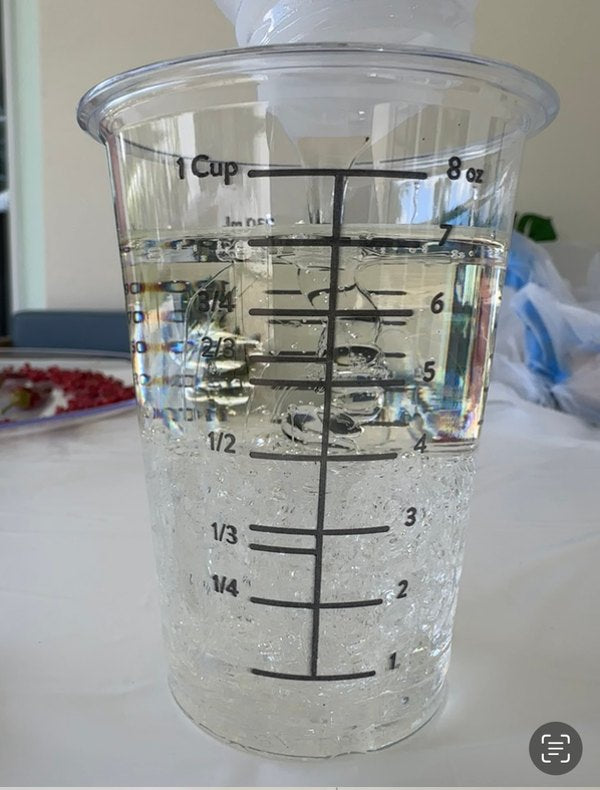

To avoid this issue, always measure your epoxy by volume. We recommend using graduated mixing containers, which have lines on the interior to indicate the current total volume. These make it incredibly easy to get a precise mixture that matches the ratio of your chosen epoxy product.

For instance, our UltraClear Deep Pour Epoxy has a 2:1 ratio. Rather than measuring by weight, e.g., 2 lb resin to 1 lb harder, you would measure by volume, such as a gallon of resin to a half-gallon of hardener. This will ensure an accurate measurement for your batch and enable the epoxy to blend well and cure strong and clear.

Mistake #3: Using components when they're too warm or cold.

The third most common mistake people tend to make is to try to mix the epoxy resin components when they're far too warm or too cold. Though cured epoxy finishes can handle a wide range of temperatures with ease, epoxy in its pre-cured liquid state is far more sensitive.

In order to mix and cure properly, epoxy resin needs to be within a particular temperature range. This temperature is typically about 75°F, though it may vary depending on the product. (e.g., for our Deep Pour Epoxy, it's 60°F to 85°F).

Attemping to use epoxy outside of its recommended range can induce a variety of different issues, such as poor or slow curing, a murky or cloudy finish, or curing that happens too quickly, preventing the epoxy from settling properly.

How to prevent this mistake:

Avoid using epoxy resin that's very warm or cold, such as that which has been sitting in an uncontrolled environment.

Mistake #4: Pouring your components into unsuitable containers.

The fourth and final mistake we see sometimes is using an unsuitable container for mixing and pouring.

Here are some examples of containers to not use:

- Polystyrene (or styrofoam) containers. Resin can react strangely to these materials.

- Uncoated paper or cardboard cups: These materials are absorbent, and the resin will soak into them.

- Containers with uncured resin: We recommend against reusing any mixing containers. At the very least, do not reuse a mixing container that still contains any remnants of a previous epoxy batch.

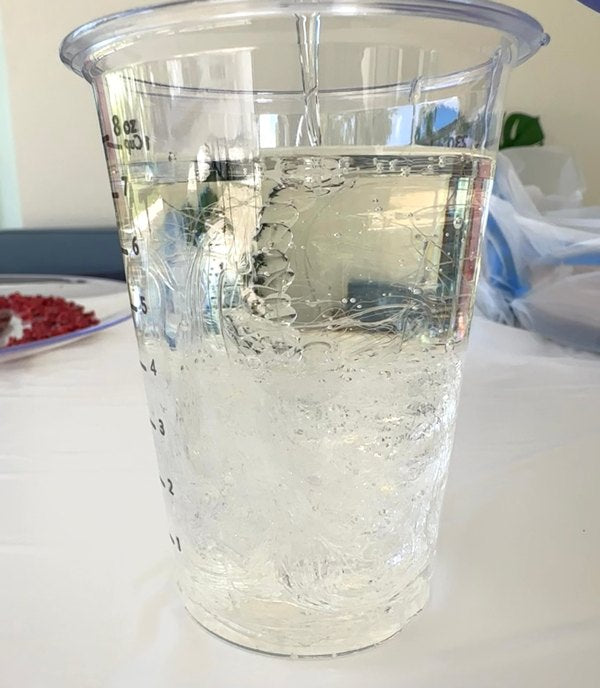

- Dirty or wet containers: Unsurprisingly, you should not mix your epoxy resin batch in a container that is dirty or wet, to avoid contamination.

How to prevent this mistake:

The ideal container for mixing your epoxy resin will be a clean, dry plastic mixing container or a silicone container. For tiny batches, plastic cups can also be used.

In our store, we carry two plastic mixing containers with graduated mixing lines:

These containers are ideal for mixing up epoxy batches, especially bigger batches meant for medium-to-large projects such as table tops, countertops, and other furniture.

Ensure your success by being prepared.

The best way to guarantee your epoxy finish turns out beautifully strong is to make sure you spend the time to read your epoxy instructions prior to beginning.

Be sure to contact the dealer if you have any questions, as they're most likely to provide you the answers you need and should be able to clarify any confusing aspects.

Have questions? Want advice? Contact us!

If you have any questions about measuring and mixing epoxy resin, or if you'd like assistance in planning an epoxy project, please reach out to us at UltraClear Epoxy—our epoxy experts are ready to assist!

You can contact us via phone or email here. During business hours, you can also text chat online with one of our resin specialists by clicking the Help button at the bottom of your screen.

In our online store, you'll find a variety of useful tools and supplies, ideal for resin projects, plus our award-winning UltraClear Bar & Table Top Epoxy and our UltraClear Deep Pour Epoxy.